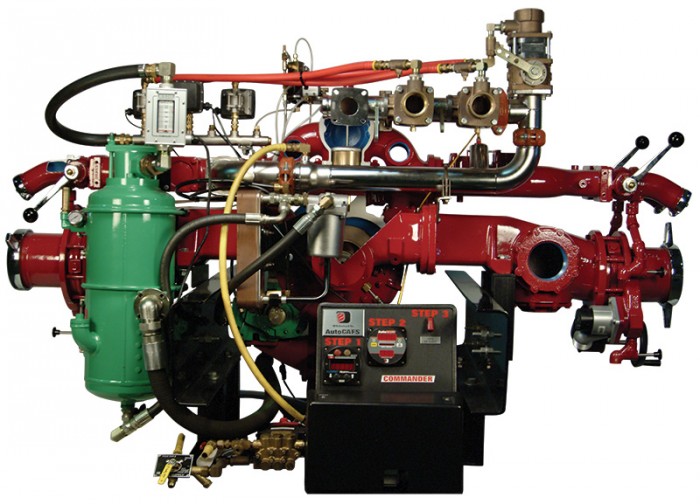

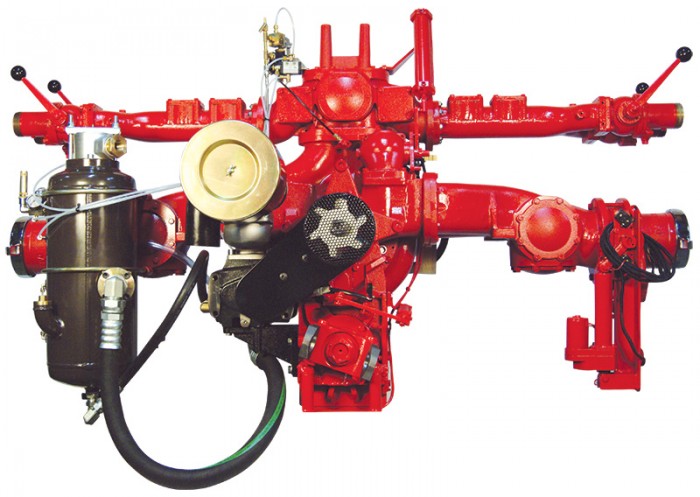

Odin® 150-200 CFM PTO Compressor Kit

Odin® 150-200 CFM PTO Compressor Kit

The air compressor must be designed to be installed on the apparatus chassis and have a 100% duty cycle. The air compressor shall be an American manufactured, continuous duty, oil-injected type, rotary screw rated up to 150 cfm @ 150 psi. Parts shall be readily available and stocked in the USA with certified service centers in all 50 states. It shall have an additional speed-up gearbox designed and integrally built by the compressor manufacturer. Compressor to have side-by-side gear set to provide for maximum ground clearance. A copy of the certification record shall be included.

The air receiver/separator (vessel) must act as an air/oil separator. The vessel shall be powder-coated carbon steel material and contain an integrated coalescing oil separator element. The vessel must have a lubricant sight glass no smaller than 2” in diameter. The pressure vessel must have a 200 psi (13.8 b) high-pressure relief valve. The vessel must have a replaceable spin-on 25-micron oil filter with safety bypass feature. It must contain an integral, pneumatically piloted blow-down valve. The vessel shall be a horizontal mount design. (A vertical mount air/oil receiver is available as an option.) The vessel shall meet all vessel ASME requirements. Oil carryover is rated 10 ppm or under at full flow.

Air Compressor

- 200 cfm (5663 L/M) @ 125 psi (8.6 bar)

- 150 cfm (4247 L/M) @ 125 psi (8.6 bar)

- PTO driven compressor

- Available in 150 and 200 cfm with inlet valve and mounting bracket

- Horizontal mount air/oil receiver

- Control panel with high temperature shut down

- Odin AutoBalance™ valve system

- Stainless steel, plate-type heat exchange with thermo valve

- American made

- Master air check valve

- Remote air intake filter kit

The air receiver/separator (vessel) must act as an air/oil separator. The vessel shall be powder-coated carbon steel material and contain an integrated coalescing oil separator element. The vessel must have a lubricant sight glass no smaller than 2” in diameter. The pressure vessel must have a 200 psi (13.8 b) high-pressure relief valve. The vessel must have a replaceable spin-on 25-micron oil filter with a safety bypass feature. It must contain an integral, pneumatically piloted, blow-down valve. The vessel shall be a horizontal mount design. (A vertical mount air/oil receiver is available as an option.) The vessel shall meet all vessel ASME requirements. Oil carryover is rated 10 ppm or under at full flow.

- 150 cfm shipping weight: 535 lbs. (242.6 kg)

- 200 cfm shipping weight: 585 lbs. (265.3 kg)

Contact Odin for schematic and CAD drawings of components.

- Mini Pumper

- Rescue pumper

- Tactical Tender

- Wildland/Interface

- Retrofit

The compressor control panel shall include the following controls and instruments. The compressor controls and instruments shall be mounted on a custom designed embossed placard. The standard panel will require the transmission to operate the PTO and be switched from the cab. The optional overspeed panel will have aftermarket controller and switch the PTO from the compressor control panel.

What Can We Do for You?

A family-run company that’s continuously raised the bar for more than a century, Darley is built upon a steadfast commitment to innovation, reliability, and relationships that add value with every interaction.