Search Results for: CS-200

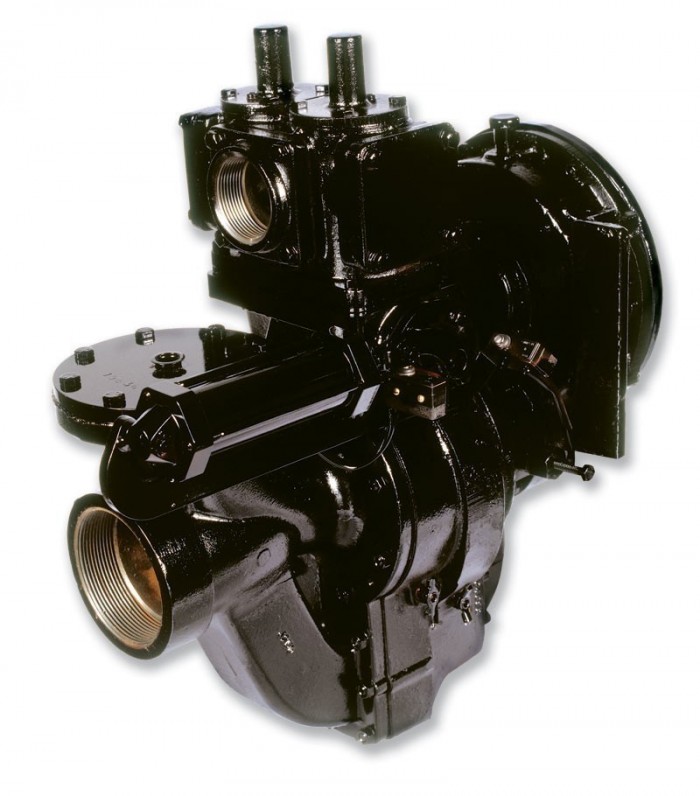

The air compressor must be designed to be installed on the apparatus chassis and have a 100% duty cycle. The air compressor shall be an American manufactured, continuous duty, oil-injected type, rotary screw rated up to 150 cfm @ 150 psi. Parts shall be readily available and stocked in the USA with certified service centers in all 50 states. It shall have an additional speed-up gearbox designed and integrally built by the compressor manufacturer. Compressor to have side-by-side gear set to provide for maximum ground clearance. A copy of the certification record shall be included.

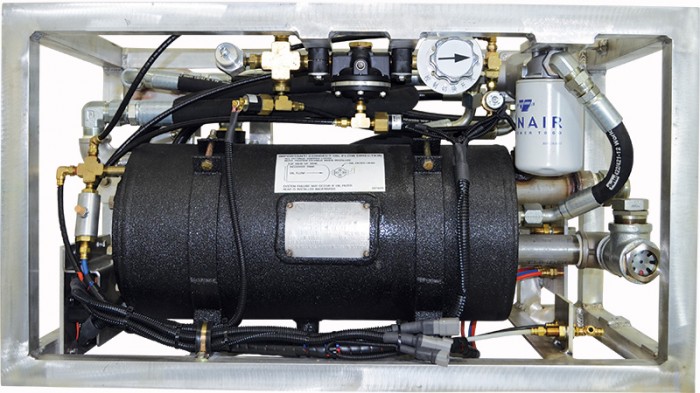

The air receiver/separator (vessel) must act as an air/oil separator. The vessel shall be powder-coated carbon steel material and contain an integrated coalescing oil separator element. The vessel must have a lubricant sight glass no smaller than 2” in diameter. The pressure vessel must have a 200 psi (13.8 b) high-pressure relief valve. The vessel must have a replaceable spin-on 25-micron oil filter with safety bypass feature. It must contain an integral, pneumatically piloted blow-down valve. The vessel shall be a horizontal mount design. (A vertical mount air/oil receiver is available as an option.) The vessel shall meet all vessel ASME requirements. Oil carryover is rated 10 ppm or under at full flow.

New PTO frame with 20% space savings. Pre-plumbed module and engineered air-end package converts new or existing apparatus into CAFS capable. Available in 150 and 200 cfm.

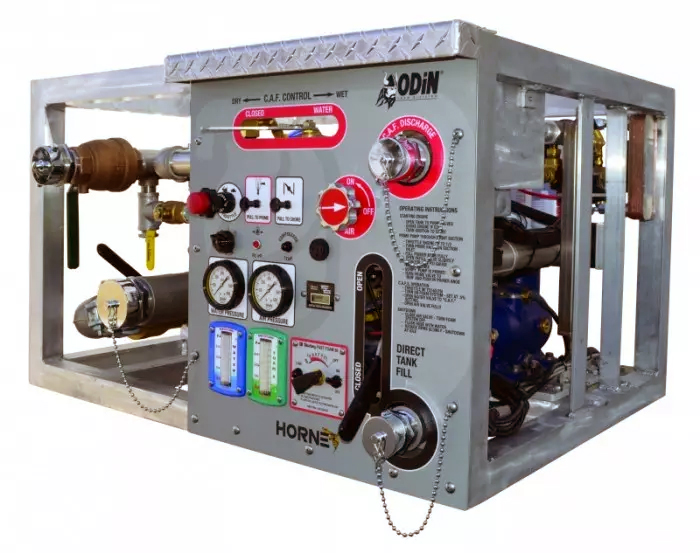

This model provides a “self-contained” gasoline-powered “slide-in” type Compressed Air Foam System (CAFS). The CAFS is designed to fit into the back of a standard length and width pick-up truck or fire service body.

The CAFS is designed to discharge water only, air only, foam solution only, or compressed air foam from the same discharge outlet. In addition, the consistency of the compressed air foam (expansion ratio), wet/dry, is fully adjustable.

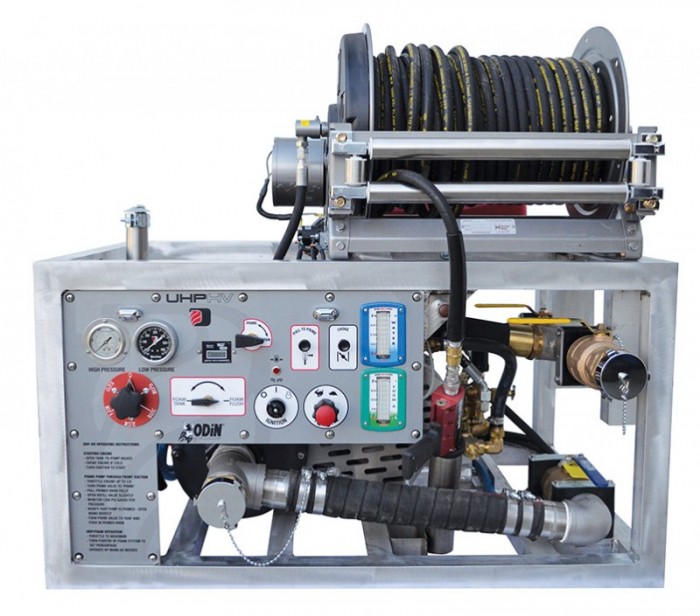

The UHP-HV® (Ultra High Pressure-High Volume) module offers the best of both worlds for the wildland-urban interface. Darley has combined our versatile direct-drive 2BE pump and the CAT 7CP high-pressure piston pump to meet all your firefighting needs in one compact package. The main pump can be used for water transfer or for 1-1/2” hose for structural attacks, while the belt-driven CAT can produce low flow high pressure flows in excess of 1300 psi with optional foam through the 1/2” HP hose.

ODIN® Foam recently introduced a new self-contained Ultra High Pressure (UHP) coupled with a High Volume (HV) pump for dual-purpose firefighting. The model UHP-HV® has received global publicity with sales throughout the US, Africa, the Middle East, and Australia.

The system is now available in both gasoline and diesel-powered versions. The diesel boasts a 24.5 HP Kubota water-cooled engine.